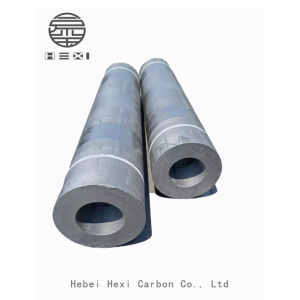

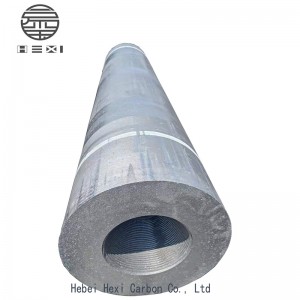

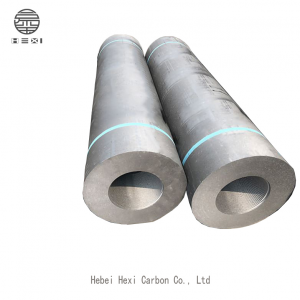

High Power Graphite electrode

Ama-electrode e-graphite aphezulu akhiqizwa nge-coke yekhwalithi ephezulu ye-petroleum (noma i-coke yenaliti yezinga eliphansi). Inqubo yokukhiqiza ihlanganisa ukubala, ukuxubha, ukuxova, ukubumba, ukubhaka, ukucwilisa, ukubhaka kwesibili, i-graphitization kanye nokucubungula. Impahla eluhlaza yengono iphuma kwamanye amazwe enaliti ye-coke, futhi inqubo yokukhiqiza ihlanganisa ukucwiliswa kabili kanye nokubhaka okuthathu. Izakhiwo zayo ezingokomzimba nezomshini ziphakeme kunalezo zama-electrode avamile we-graphite wamandla, afana nokumelana okuphansi nokuminyana kwamanje.

Isetshenziswa Emayini Esithandweni Sogesi

esetshenziswa ezithandweni zikagesi ukuze kukhiqizwe ama-alloys ensimbi, i-silicon emsulwa, i-phosphorus ephuzi, i-calcium carbide ne-matte, ebonakala yiqiniso lokuthi ingxenye engezansi ye-electrode eqhubayo ingcwatshwa ngokukhokhiswa, ukuze ngaphezu kokushisa okukhiqizwa yi-electrode. i-arc kagesi phakathi kwepuleti nokushaja, ukushisa nakho kukhiqizwa ukumelana nokushaja njengoba okwamanje kudlula kuwo.

Izinga lamandla aphezulu we-graphite electrode nengono

I-HP Graphite electrode Umthwalo wamanje ovumelekile

I-Hexi Carbon yinkampani ekhiqizayo ekhiqizayo, edayisayo, ethumela kwamanye amazwe futhi ehlinzeka ngama-electrode e-graphite anamandla amakhulu ukuze asetshenziswe kabanzi. Inkampani yethu ibilokhu ikhuthaza ukusetshenziswa kwezinto ezingcono kanye nobuchwepheshe bokukhiqiza obusezingeni eliphezulu ukuze kwehliswe ukusetshenziswa kwamandla nezindleko zemikhiqizo. I-electrode enamandla kakhulu ye-graphite ekhiqizwa yinkampani yethu inezici zokuminyana okuphezulu, ukusetshenziswa kwamandla okuphansi kanye nokuhamba okuphezulu. Inkampani yethu ithembisa ukubonisana nokufakwa kwamahhala, ukulandelela kwamahhala ngemva kokuthengisa kanye nokubuyiselwa okungenamibandela kwezinkinga zekhwalithi.

Ukuthuthwa kwama-electrode

Uma usebenzisa i-forklift ukuthutha ama-electrode astakiwe, kufanele kuqashelwe ukugwema ukungqubuzana. Ungqimba olulodwa kuphela oluvunyelwe ukufakwa ngesikhathi, futhi ukunakwa kufanele kukhokhwe ebhalansi nokuqondanisa ukuze kuvinjelwe ukushelela nokuphuka.