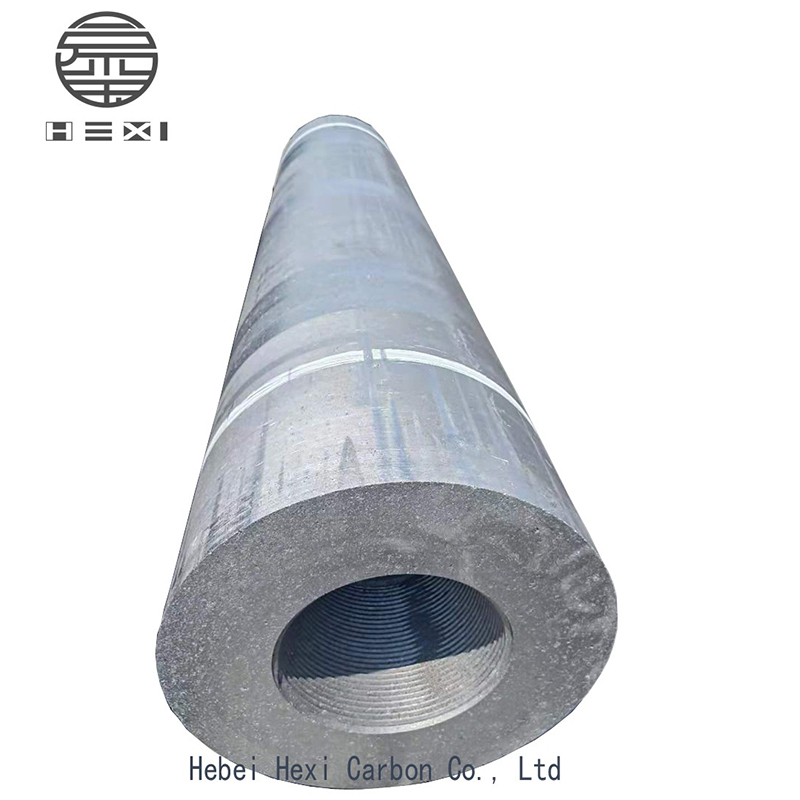

450mm amandla aphezulu e-graphite electrod

I-HP graphite electrode yenziwe ikakhulukazi nge-petroleum coke ne-coke yenaliti, Iyakwazi ukuthwala ukuminyana kwamanje 18-25A/cm2. Yakhelwe amandla aphezulu okwenza insimbi ye-arc yomlilo kagesi.

| Ukuqhathanisa Ukucaciswa Kwezobuchwepheshe kwe-HPI-Graphite Electrode18″ | ||

| I-Electrode | ||

| Into | Iyunithi | Ukucaciswa Komhlinzeki |

| Izici Ezijwayelekile Ze-Pole | ||

| Ububanzi Okuzisholo | mm | 450 |

| I-Max Diameter | mm | 460 |

| Ububanzi obuncane | mm | 454 |

| Ubude Begama | mm | 1800-2400 |

| Ubude obukhulu | mm | 1900-2500 |

| Ubude obuncane | mm | 1700-2300 |

| Ukuminyana kwenqwaba | g/cm3 | 1.68-1.73 |

| amandla aphambene | I-MPa | ≥11.0 |

| Young' Modulus | I-GPa | ≤12.0 |

| Ukumelana Okuqondile | µΩm | 5.2-6.5 |

| Ubuningi bokuminyana bamanje | KA/cm2 | 15-24 |

| Ikhono Lamanje Lokuthwala | A | 25000-40000 |

| (CTE) | 10-6℃ | ≤2.0 |

| okuqukethwe komlotha | % | ≤0.2 |

| Izimpawu Ezijwayelekile Zengono (4TPI/3TPI) | ||

| Ukuminyana kwenqwaba | g/cm3 | 1.78-1.83 |

| amandla aphambene | I-MPa | ≥22.0 |

| Young' Modulus | I-GPa | ≤15.0 |

| Ukumelana Okuqondile | µΩm | 3.5-4.5 |

| (CTE) | 10-6℃ | ≤1.8 |

| okuqukethwe komlotha | % | ≤0.2 |

Indlela yokunciphisa ukusetshenziswa kwama-electrode

Eminyakeni yamuva nje, ngokuthuthukiswa okunamandla kwemboni yensimbi yesithando somlilo waseChina, kanye nezidingo zochwepheshe bokonga nokunciphisa ukusetshenziswa kwamandla kanye nezazi ekhaya nakwamanye amazwe baphetha ezinye zezindlela eziphumelelayo kanje:

I-1.I-anti-oxidation mechanism ye-spray yamanzi i-graphite electrode

Ngocwaningo lokuhlola, ukufafaza isixazululo se-anti-oxidation ebusweni bama-electrode sekufakazele ukuthi kungcono kakhulu uma umiswa kusuka ku-oxidation eseceleni ye-graphite electrode, futhi amandla e-anti-oxidation anda izikhathi ezi-6-7. Ngemuva kokusebenzisa le ndlela, ukusetshenziswa kwe-electrode kwehle kwafinyelela ku-1.9-2.2kg ukuncibilikisa ithani lensimbi.

2.I-electrode engenalutho

Eminyakeni yamuva, iNtshonalanga Yurophu neSweden aqale ukusebenzisa ama-electrode angenalutho ekukhiqizeni iziko lensimbi ye-ferroalloy. Ama-electrode angenalutho, umumo wesilinda, ngokuvamile awanalutho ngaphakathi avalwe ngegesi engasebenzi. Ngenxa yokungabi nalutho, izimo zokubhaka ziba ngcono futhi zenze amandla e-electrode abe phezulu. Ngokuvamile, ingonga ama-electrode ngo-30% -40%, kuze kufike ku-50% kakhulu.

3.DC isithando somlilo

I-DC electric arc furnace iwuhlobo olusha lwesithando somlilo esincibilikisa i-arc esisanda kwakhiwa emhlabeni eminyakeni yamuva nje. Kusukela kudatha eshicilelwe phesheya, i-DC arc furnace ingenye yezindlela eziphumelela kakhulu zokunciphisa ukusetshenziswa kwama-electrode. Ngokuvamile, ukusetshenziswa kwama-electrode kungancishiswa cishe ngo-40% kuya ku-60%. Ngokwemibiko, ukusetshenziswa kwe-graphite electrode yesithando somlilo esinamandla amakhulu we-DC yehliswe kwaba ngu-1.6kg/t.

4.Electrode surface enamathela ubuchwepheshe

Ubuchwepheshe be-Electrode coating ubuchwepheshe obulula nobusebenzayo bokunciphisa ukusetshenziswa kwama-electrode, ngokuvamile bunganciphisa ukusetshenziswa kwama-electrode cishe ngama-20%. Izinto zokumboza ze-electrode ezivame ukusetshenziswa ziyi-aluminium kanye nezinto ezihlukahlukene zobumba, ezinokumelana ne-oxidation okuqinile emazingeni okushisa aphezulu futhi zinganciphisa ngempumelelo ukusetshenziswa kwe-oxidation yendawo eseceleni ye-electrode. Indlela yokugcoba i-electrode ngokuyinhloko ngokufafaza nokugaya, futhi inqubo yayo ilula futhi kulula ukuyisebenzisa. Kuyindlela evame ukusetshenziswa kakhulu yokuvikela ama-electrode.

5.I-electrode efakiwe

Gcoba ama-electrode esixazululweni samakhemikhali ukuze ubangele ukusebenzisana kwamakhemikhali phakathi kwendawo ye-electrode nama-ejenti ukuze kuthuthukiswe ukumelana kwe-electrode ku-oxidation yezinga lokushisa eliphezulu. Lolu hlobo lwama-electrode lunganciphisa ukusetshenziswa kwama-electrode cishe ngo-10% kuya ku-15%.